CIRCULAR ECONOMY

CIRCULAR ECONOMY

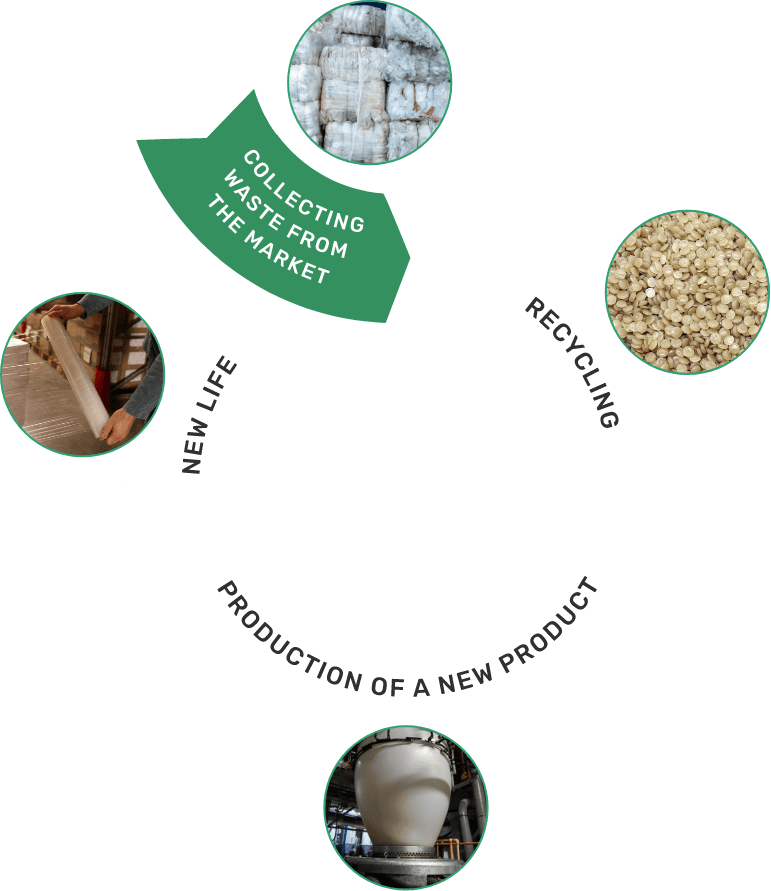

CONTALEN CLOSED LOOP

ECONOMY LEADER

By introducing innovative recycling technology, we have become one of the leaders of the circular economy. We pursue a sustainable development model, counteract the excessive consumption of natural resources and carbon emissions.

enter the oceans each year

in circulation is recycled

contain more plastic than fish

2050

ENVIRONMENTAL DISASTER?

The permanent extraction of fossil fuels that are running out is used to make plastic products from them. After a single use, most end their lives in a landfill or incinerator. Furthermore, 8 million tons of plastic enter the oceans each year – a number that continues to rise. If we fail to introduce rapid changes, by 2050 the oceans will contain more plastic than fish.

Only 14% of plastic packaging in circulation is recycled. As a result, the economy loses the equivalent of $80-120 billion a year, but what is even worse is the constant increase of carbon emission into the atmosphere.

The belief that banning plastics and replacing them with materials like glass, paper or aluminium will solve the problem is wrong. Swapping plastic for other raw materials may lead to a number of unintended negative consequences, such as: increased carbon emissions, water consumption and food waste. So we need to switch to recycling, which is an integral part of the circular economy.

ACP TECHNOLOGY

REGRANULATES FROM SELECTIVE COLLECTION

The ACP technology we implemented is a cure for these environmental problems. It is supported by 30 years of recycling experience and the outcome of years of R&D work.

The ACP technology led an innovative product – the PE regranulate – produced using polyethylene waste from selective collection. Our production capacity increased by 80%, and 100 tons of plastic waste is being recycled every day. The parameters of Contalen regranulate are similar to the original raw material, but significantly exceed the properties of regranulate produced using traditional methods.

OUR MISSION

WE GIVE WASTE A SECOND LIFE

- Reduced CO2 emissions by up to 90% and a positive impact on climate change

- Best alternative to fossil fuels

- Reduced dependence on natural resources (natural gas, oil)

- Reduced release of plastic waste into the environment

- No burning or storage of plastics causing the release of toxic toxins and gases

WOULD YOU LIKE TO KNOW MORE?

GET IN TOUCH

+48 606 666 111