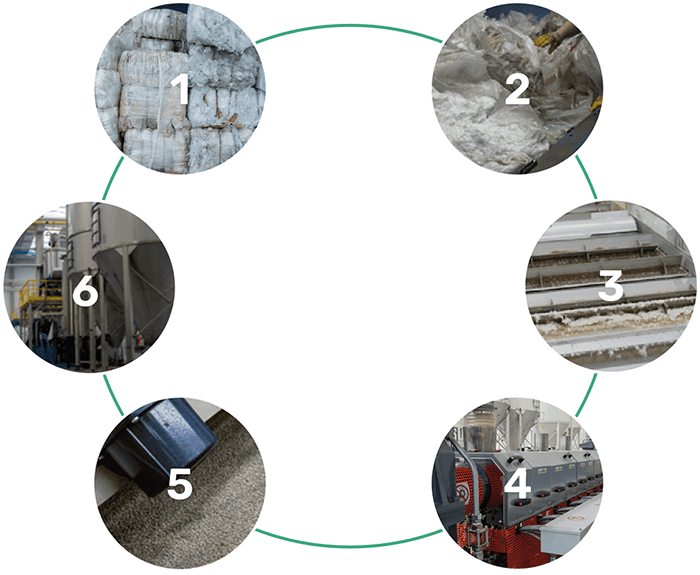

TECHNOLOGICAL PROCESS

REGRANULATE PRODUCTION PROCESS

Find out more about the multi-stage technological process of regranulate production.

contalen

FIND OUT MORE ABOUT THE tECHNOLOGICAL PROCESS

Conversion of waste polyethylene film into finished Contalen pellets takes a multi-stage process. This process is not only grinding, feeding into the extrusion system, plasticizing and granulation.

It also includes the stage of the removing of solid and fibrous contaminants, such as metal and wood chips, paper or textile fibres, or chemicals such as ink. Lines designed for a specific application are based on the following sequences of subprocesses and equipment.

TECHNOLOGICAL PPROCESS

A SECOND LIFE FOR WASTE

1. Raw material

Waste arrives in compressed bales

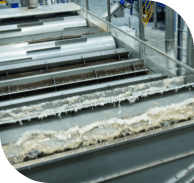

3. Cleaning

Shredded plastic is cleaned in a washing system

5. Drying

Finished regranulate is dried

2. Sorting

Waste from bales is sorted

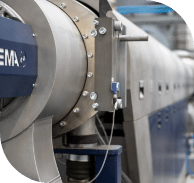

4. Extrusion

Washed film flakes undergo homogenisation, degassing and are filtered

6. Averaging

Finished regranulate is mixed and averaged

“We cannot eliminate the plastics, it is a too valuable material. RECYKLING is the shortest path to achieve sustainable development.”

Managing Director of Conkret

WOULD YOU LIKE TO KNOW MORE?

GET IN TOUCH

+48 606 666 111